Technology Services

Know How and Technology - From the Idea to the Application

The department Technology is part of the engineering department of the Department of Physics and essentially consists of the three subject areas of metallic glasses, probe microscopy and construction of apparatus. The main focus is aimed at the cooperation between academia and industry which is highly application-oriented. We make important contributions within the technology transfer between universities, universities of applied sciences, high schools and industry partners. Also, other services like occupational health and safety, as well as public relations and house services are affiliated to the Technology department.

Reimann Brake Ramp for planar flow casting processes and analysis of ribbon gluing

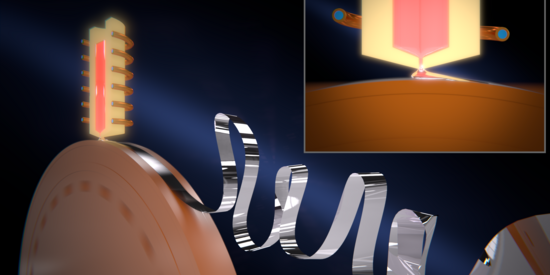

Planar flow casting is a rapid solidification process used to manufacture thin, metallic ribbons, and foil well established at the Department of Physics. In this work published in Journal of Materials Research and Technology, researchers focused on a new method to control the ribbon thickness over a length of 50 m by reducing the wheel speed at the start of the cast. This method was not already reported and was named using his inventor’s name as Reimann Brake Ramp. Moreover, the development of an automatized melt spinner permitted monitoring and controlling the process parameters, elucidating the ribbon’s gluing phenomenon during the starting phase.

Original article: "Reimann Brake Ramp for planar flow casting processes and analysis of ribbon gluing", Laurent Marot, Silvester Jakob, Marco Martina, Peter Reimann†, Heinz Breitenstein, Michael Steinacher, Ernst Meyer, Journal of Materials Research and Technology, https://doi.org/10.1016/j.jmrt.2021.11.129

What is rippling ribbons?

Video: https://gfm.aps.org/meetings/dfd-2018/5b9ada89b8ac3105e5ac8e25

The group of technology of the Department of Physics published a video of “rippling ribbons” to the Gallery of Fluid Motion competition held at the last annual APS/DfD meeting. This video described a phenomenon during planar flow casting of amorphous metallic ribbons.

Moreover, the use of these amorphous metallic ribbons and the collaboration with industry is explained here.

https://www.unibas.ch/de/Aktuell/News/Uni-Research/Metallisches-Glas-fuer-die-Industrie.html

Amorphous foils as Metallic Glass

Metallic glasses are amorphous metals. They consist in different metal alloys, depending on their intend use. Applications as core material in power transformers or as active brazing foils for joining engineering ceramics are typically.

Metallic Glass as Brazing Foils

The metallically shining appearance is typical for the metallic glass foils. They look like aluminium foil as we know them from the household. However, tin-foils are produced under big energy involved by gradual roll down of the aluminium blocks. In contrast, the metallic glasses are manufactures by pouring the melt directly in one step onto the spinning wheel adjusting the desired thickness. This procedure is called Melt Spinning.

Investigation on the structure of metallic glasses:

Chain-like structure elements in Ni40Ta60 metallic glasses observed by scanning tunneling microscopy, R. Pawlak, L. Marot, A. Sadeghi, S. Kawai, Th. Glatzel, P. Reimann, S. Goedecker, H.-J. Güntherodt, E. Meyer, Nature Scientific reports, 5, (2015), 13143

Manufacturing Process

The liquid alloy is squeezed through a small slit at the nozzle bottom with light overload pressure onto the surface of a rotating copper wheel. The melt solidifies instantly. The typical cooling rate is 1 million degrees per second. The resulting metallic glass is amorphous and only about 50 micrometers thick. This specific foil production process directly from the melt without rolling is very efficient and saves a lot of energy. Applications as core material in power supplies and distribution transformers are typical. Energy-savings and improvements in the economy are the advantages. Further applications to use them as active brazing foils to join engineering ceramics are increasing.

Applications

For more than 20 years the Department of Physics, in close collaboration with Endress+Hauser Maulburg (Germany) and Flowtec (Switzerland), has developed a specific metallic foil for industrial applications for sensor in pressure measurements (details above).

Metallic foils are used to welled ceramic parts from a pressure measurements system from Endress+Hauser.

We give technical support in device developments for scientific applications, mechanical constructions in micro technic or in vacuum technology. In our special workshop we are able to machine materials by ultrasonic power, diamante sawing or glass blower treatments. Furthermore, we offer support in optical microscopy and we are equipped with basic devices for digital imaging and video productions.

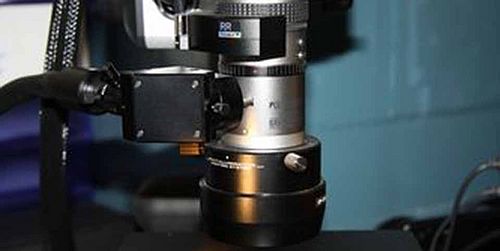

Melt Spinner

Melt Spinner for the production of metallic glass foil. A new automatized system was design to monitor and controlled the process for the production of metallic glass.

Double electric arc furnace for alloy production

Classical arc furnace for alloy production are using one electrical arc and to have a better control of the melting a double arc was developed and constructed.

Magnetron Sputtering Process

In our facility, we deposit by magnetron sputtering metal, oxide films for several applications. Example are TiAlN for mechanical properties, rhodium for watch industry. Rare-earth oxide surfaces were recently reported to possess intrinsic hydrophobicity in Külah, E., Marot, L., Steiner, R., Romanyuk, A., Jung, T. A., Wäckerlin, A., & Meyer, E. (2017). Surface chemistry of rare-earth oxide surfaces at ambient conditions: reactions with water and hydrocarbons. Scientific Reports, 7, 43369.

Rare earth oxides (red/orange) react with gaseous organic compounds from the ambient air to form carbonates and hydroxides (grey/white). Through this reaction, the surface develops water-repelling properties.

Sun Protection Glasses

M-Glass: Innovative coatings for sun protection glasses based on the theory of optimized spectral transmittance.

These coatings reduce the solar-thermal load of building's interior by one third in comparison to current sun protection glasses on the market. Apart of the comfort improvement for occupants, the energy necessary for cooling of buildings is reduced. Therefore these new coatings can contribute to the measures needed to reduce global climatic changes.

For more information, please click here.

Within several different projects, in close collaboration with Glas Trösch and others, the Department of Physics contributed to develop innovative coatings for the market.

We analyze and examine technical surfaces and more...

As a competent user service lab with main focus on Scanning Probe Microscopy we carry out analytical and user-related investigations on practically all kind of technical surfaces. The lab is also open to students and researchers of other groups within the Physics Department to perform measurements on their own after training. Besides Atomic Force Microscopy (AFM) and Scanning Tunneling Microscopy (STM), other imaging surface technologies like Confocal Laser Scanning Microscopy and Scanning Electron Microscopy (SEM) are also used for our analysis.

While AFM and SEM are powerful instruments to image the surface morphology of a specimen, X-ray photoelectron spectroscopy (XPS) is a widely used method of determining the chemical composition of a surface, this technique is also available for investigation.

In collaboration with the Nano Imaging Lab of the Swiss Nanoscience Institute these other techniques are also available.

The Department of Physics hosts and participates in numerous information, education and physics events of the University, in the region and throughout Switzerland, e.g. Saturday Morning Physics, Infotag, Future Day. There prospective students and the general public can get an insight into the degree programs we offer but also learn about our most recent research results. An overview over the upcoming events you will find here.

In addition to that we organise lectures and/or lab tours for high schools, associations or the general public. In case you would be interested, please contact us.

The technology group organises and/or supports the above mentioned activities especially regarding the technical aspects and the experiments.

Contact

Department of Physics

University of Basel

Klingelbergstrasse 82

4056 Basel, Switzerland

hilfsassistenz-physik@clutterunibas.ch

T +41 (0)61 207 37 16

Head of Technology Services

Team

Quick Links